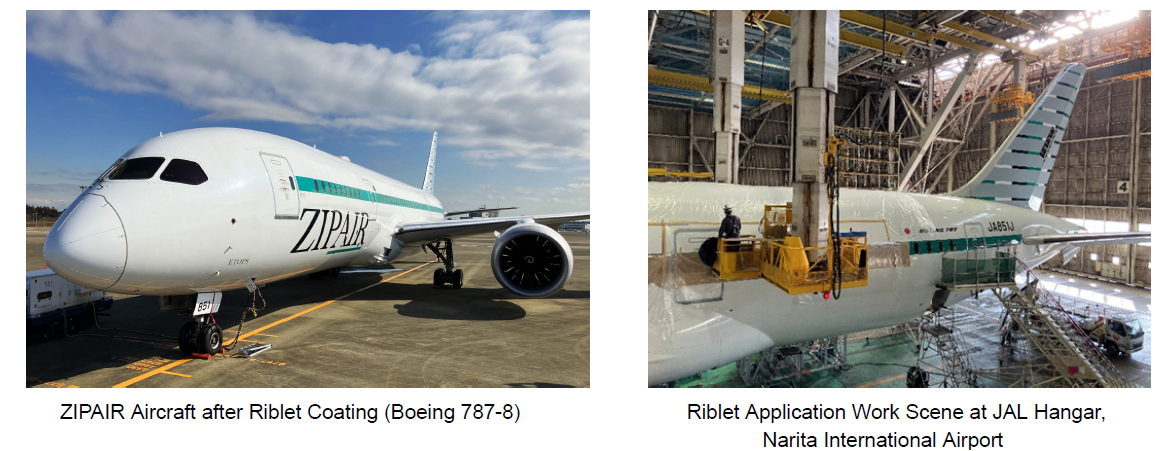

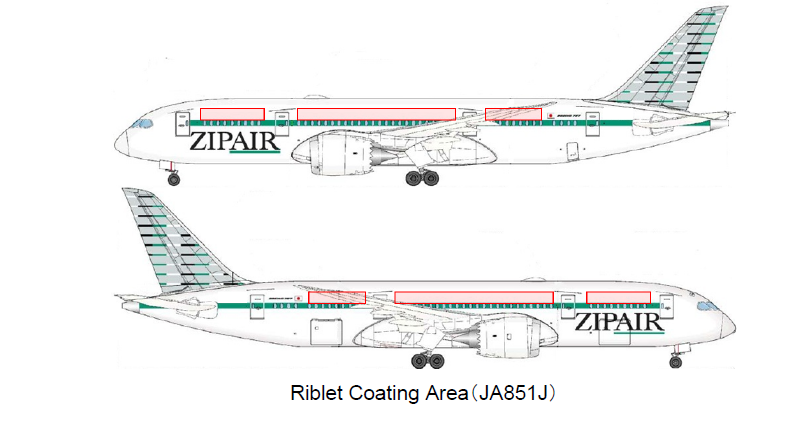

Japan Airways Co., Ltd. (headquarters: Shinagawa-ku, Tokyo; president: Mitsuko Tottori; hereinafter “JAL”), the Japan Aerospace Exploration Company (headquarters: Chofu Metropolis, Tokyo; president: Hiroshi Yamakawa; hereinafter “JAXA”), O-Properly Company (headquarters: Nishiyodogawa-ku, Osaka; president: Yasuharu Kawato; hereinafter “O-Properly”), and ZIPAIR Tokyo Inc. (Headquarters: Narita Metropolis, Chiba, President: Shingo Nishida, hereinafter “ZIPAIR”) has utilized the ribbed (*1) coating to the aspect of the fuselage of Boeing 787-8 plane (JA851J) for the primary time. The plane entered service on worldwide routes from January 27, 2026.

By way of this initiative, JAL, JAXA, O-Properly and ZIPAIR will proceed to work collectively to advance plane decarbonization by lowering drag throughout cruising, bettering gas effectivity and lowering CO2 emissions.

ZIPAIR, a medium to long-haul low-cost airline (LCC) of the JAL Group, obtained a CO2 neutrality certification in Could 2025, verified underneath the worldwide normal “ISO 14068-1:2023” and promotes the discount of CO2 emissions. As a part of these efforts, the riblet coating was utilized.

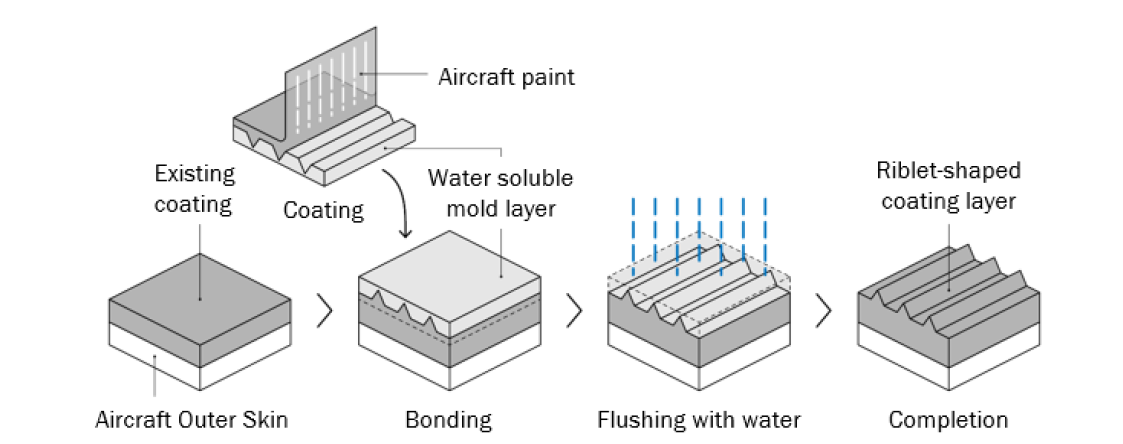

This software was first applied on an plane of ZIPAIR, the low-cost airline (LCC) of JAL Group. As earlier than, the ribbed coating was utilized to the fuselage of the plane utilizing the repeatedly improved “Paint-to-Paint technique” (*2).

This time, the standard and effectivity of the appliance have been improved by the brand new introduction of plate positioning mildew and bettering the shrinking mildew of the rib forming plate. The appliance was efficiently accomplished at Narita Worldwide Airport, ZIPAIR’s upkeep base, subsequent to Haneda Worldwide Airport.

Paint-to-Paint Methodology: A way through which a textured coating is utilized to the prevailing paint movie utilizing a water-soluble mildew

As well as, the appliance on JAL’s Boeing 787-9 plane (JA868J) (*3), which has been flying with large-scale riblet coating since January 18, 2025, was prolonged to the higher fuselage in November 2025 and continues to function on worldwide routes. In keeping with JAXA’s estimated drag discount evaluation utilizing ribs, the expanded coating on the higher hull improved the drag discount whereas crusing from 0.24% to 0.31%, leading to an anticipated annual discount of roughly 154 tons of gas consumption and 492 tons of CO2 emissions (*4).

As well as, a brand new rib form with higher drag discount – the sharp single-chamfered riblet (*5) – is being researched and developed and its in-flight sturdiness is being evaluated.

This initiative has been promoted by means of the joint demonstration applications underneath the JAXA Area Innovation by means of Partnership and Co-creation (J-SPARC) program (*6). We’ll proceed to confirm the sturdiness and aesthetics of the rib-shaped coating, in addition to its results on bettering gas effectivity on long-haul worldwide flights, and increase the variety of plane and software areas, additional selling the decarbonization of plane.

(*1) Riblet: Positive groove construction impressed by the form of shark pores and skin, which reduces water resistance. By forming a high quality groove construction on the outer panel of the plane alongside the airflow throughout flight, the drag may be diminished.

(*2) Paint-to-paint technique: A way through which a textured coating is utilized to the prevailing paint movie utilizing a water-soluble mildew. Joint patent of O-Properly and JAXA (patent no. 6511612).

(*3) January 24, 2025 Press launch: World’s first plane with large-scale riblet coating launched on worldwide routes

https://press.jal.co.jp/en/release/202501/008590.html

(*4) The anticipated impact of flying the route for one 12 months, calculated primarily based on JAXA’s estimated drag discount share and gas consumption on the Narita-Frankfurt route prior to now 12 months.

(*5) With a cross-section much like that of a single bevel kitchen knife, the sharp single bevel rib displays an improved discount in pores and skin friction resistance of roughly 6 to six.5 %, whereas standard ribs obtain roughly 5 %. (Japanese Patent No. 7770011: Riblet Construction and Object, US Patent US 12,415,596 B2: Riblet Construction and Object) Japanese Patent)

(*6) “Area Innovation by means of Partnership and Co-creation (J-SPARC)” is considered one of JAXA’s industrial promotion applications, underneath which the challenge entitled “Growth of Superior Plane riblet” is collectively demonstrated,

https://aerospacebiz.jaxa.jp/en/solution/